Managing abrasive fluids mixed with solids is one of the most challenging tasks in industries such as mining, dredging, wastewater treatment, and construction. A submersible slurry pump offers an efficient solution by operating directly in the slurry, eliminating priming issues and ensuring reliable performance even under the most demanding conditions. With their heavy-duty construction and ability to handle high-solid-content fluids, these pumps have become the go-to choice for demanding projects where durability, efficiency, and minimal downtime are crucial.

What is a Submersible Slurry Pump?

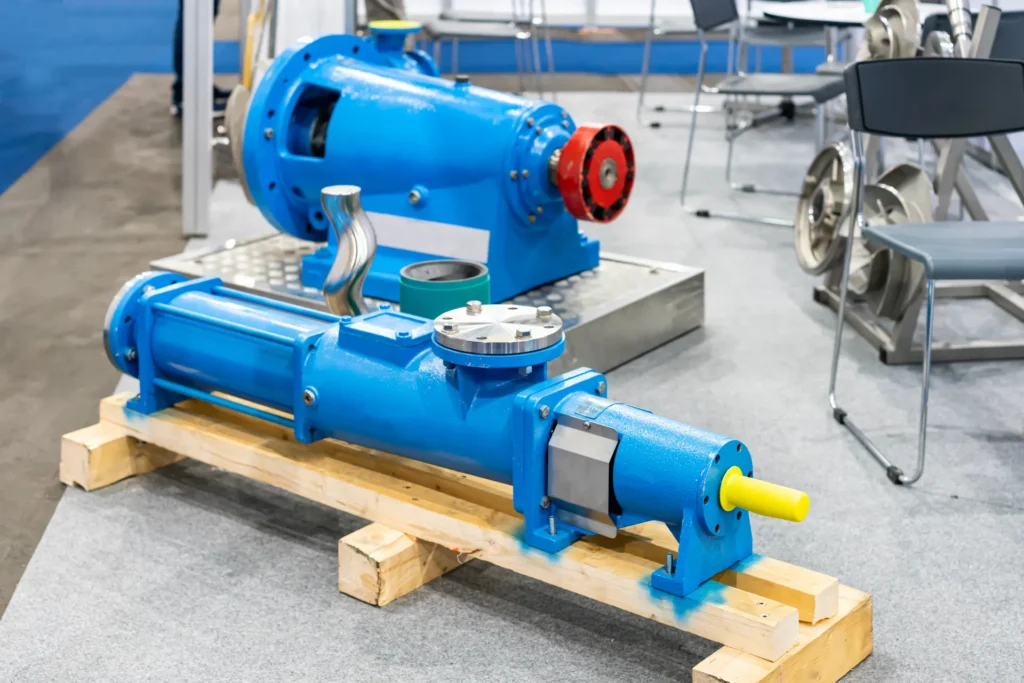

A submersible slurry pump is a heavy-duty pumping device designed to operate while fully submerged in liquid, making it ideal for handling abrasive mixtures of water and solids. Unlike conventional slurry pumps that require external priming or above-ground installation, submersible slurry pumps are placed directly into the fluid being processed. This design minimizes the risk of cavitation, reduces the need for additional suction piping, and ensures continuous, efficient operation in demanding environments.

One of the key differences between a submersible slurry pump and other types of slurry pumps lies in its ability to manage high concentrations of solids while working underwater. These pumps are specifically designed with hardened materials, protective coatings, and abrasion-resistant impellers to withstand harsh conditions in mining, dredging, wastewater treatment, and construction projects.

Key Characteristics of Submersible Slurry Pumps

- Operates fully submerged, eliminating priming issues and allowing direct immersion in slurry.

- Handles abrasive, high-solid-content fluids – ideal for environments with sand, silt, tailings, or sludge.

- Heavy-duty construction for durability – reinforced housings, wear-resistant impellers, and robust sealing systems ensure long service life.

Submersible vs. Horizontal vs. Vertical Slurry Pumps

To understand the unique value of submersible slurry pumps, it helps to compare them with horizontal and vertical slurry pump configurations:

| Feature | Submersible Slurry Pump | Horizontal Slurry Pump | Vertical Slurry Pump |

| Installation | Fully submerged | Ground-mounted | Semi-submerged |

| Space Requirement | Compact | Requires more space | Medium |

| Maintenance | Easier, fewer alignments | More frequent checks | Moderate |

| Solids Handling | High | Medium | Medium |

Working Principle of a Submersible Slurry Pump

The working principle of a submersible slurry pump is straightforward yet highly effective, making it the preferred choice for industries that deal with abrasive and solid-laden fluids. Unlike surface-mounted pumps, these units are installed directly into the slurry, where the motor and impeller are submerged and operate underwater. This eliminates suction lift limitations, reduces the risk of cavitation, and enables consistent pumping performance even in challenging environments.

Step-by-Step Process

- Motor activation – The pump’s motor, usually sealed against water ingress, provides direct power to the impeller.

- Impeller rotation – As the impeller spins, it generates a strong centrifugal force.

- Slurry movement – The centrifugal force lifts and accelerates the slurry mixture, causing it to be pushed into the casing.

- Discharge flow – The pressurized slurry is expelled through a discharge line for transport or processing.

The Role of the Impeller

At the heart of every submersible slurry pump is the impeller. Its design directly influences efficiency, wear resistance, and the pump’s ability to handle large solid particles.

- Open impellers Are Better Suited for slurries with high solid content, as they reduce clogging.

- Closed impellers offer higher efficiency in controlled environments, particularly for smaller particle sizes.

Sealing and Protection Features

Since the motor is submerged, sealing systems are critical. High-grade mechanical seals and protective housings keep water and slurry from entering the motor chamber. In heavy-duty electric submersible slurry pumps, these seals are often supported by additional lubrication systems to extend service life.

By combining compact installation with reliable operation underwater, the submersible slurry pump simplifies fluid handling in industries where other pump types would struggle to perform efficiently.

Types of Submersible Slurry Pumps

Submersible slurry pumps are not one-size-fits-all. Their designs vary to meet the unique demands of industries such as mining, dredging, construction, and wastewater treatment. Understanding the different types helps decision-makers select the most suitable pump for their specific application.

Standard Submersible Slurry Pumps

These are the most common models, engineered for general slurry handling tasks. They feature robust impellers and wear-resistant casings that are capable of handling abrasive mixtures with medium to high solid content.

Key Uses:

- Mining tailings ponds

- Sand and gravel pumping

- Industrial wastewater

Electric Submersible Slurry Pumps

An increasingly popular choice, the electric submersible slurry pump combines energy efficiency with automation-friendly control. These pumps are designed for applications requiring continuous operation with minimal human intervention.

Advantages of Electric Submersible Slurry Pumps:

- Easy remote operation and monitoring

- Lower emissions compared to diesel-driven units.

- Reduced maintenance requirements due to fewer moving parts

- Safer operation in hazardous or confined environments

Submersible Slurry Pumps with Agitators

Some models are fitted with an integrated agitator at the suction side, designed to stir up settled solids and prevent clogging. This makes them highly effective for thick sludge, dredging sediment, or applications with rapidly settling particles.

Ideal Applications:

- Harbor and port maintenance

- Sludge removal from tanks or lagoons

- Heavy construction slurry

Key Applications Across Industries

The versatility of a submersible slurry pump makes it indispensable across industries where abrasive, solid-laden fluids need to be transported efficiently. Because these pumps are designed to work directly in the slurry, they eliminate priming issues and deliver reliable performance under harsh conditions.

Mining and Mineral Processing

- Transporting mine tailings and waste slurries

- Moving ore slurries during mineral separation processes

- Ensuring continuous operations in abrasive environments

Benefit: Reduces downtime while handling highly abrasive materials.

Dredging and Marine Operations

- Removing sand, silt, and sediment from rivers, lakes, and harbors

- Maintaining navigable waterways for shipping and transport

- Supporting coastal protection and reclamation projects

Benefit: Compact installation and ability to run underwater make them ideal for confined dredging tasks.

Wastewater and Municipal Facilities

- Pumping sewage sludge and biosolids

- Handling grit, rags, and debris in treatment plants

- Supporting emergency floodwater removal

Benefit: Provides dependable solids-handling with minimal risk of clogging.

Construction and Tunneling Projects

- Dewatering excavation pits filled with slurry and sediment

- Removing bentonite and concrete slurries from tunneling operations

- Supporting foundation and piling work where water inflow is a challenge

Benefit: Easy mobility and full submersion capability simplify on-site operations.

Mini-Table: Applications at a Glance

| Industry | Example Use | Advantages of Submersible Slurry Pumps |

| Mining | Tailings transport | Handles abrasives with high efficiency |

| Dredging | Harbor sediment removal | Continuous underwater operation |

| Wastewater | Sludge pumping | Reliable, clog-resistant performance |

| Construction | Excavation slurry removal | Compact, easy to deploy onsite |

Factors to Consider When Selecting a Submersible Slurry Pump

Choosing the right submersible slurry pump is more than just matching flow rates and discharge heads. The correct selection ensures long-term efficiency, durability, and cost-effectiveness in environments where downtime can be extremely costly. Below are the critical factors decision-makers should evaluate:

1. Material of Construction

The pump must withstand constant exposure to abrasive and corrosive fluids.

- High-chrome alloys offer excellent wear resistance for mining and dredging applications.

- Stainless steel – preferred for corrosive wastewater or chemical applications.

- Elastomer-lined options – reduce wear in specific conditions.

2. Solids Handling Capacity

The size and concentration of solids determine whether a pump can perform without frequent clogging or wear.

- Check the maximum particle size rating.

- Consider slurry density and viscosity.

- For rapid-settling slurries, an agitator-equipped electric submersible slurry pump may be required.

3. Motor Power and Efficiency

The motor rating must align with the slurry load and duty cycle.

- Electric submersible slurry pumps are preferred for their continuous and energy-efficient operations.

- Evaluate motor protection features, such as thermal sensors and water intrusion alarms.

- Always account for surge loads during startup.

4. Installation Environment

The pump must be suitable for the depth and conditions of deployment.

- Depth rating – ensure compatibility with operating depth.

- Corrosiveness – seawater, acidic mine water, or industrial effluents may require upgraded materials.

- Mobility requirements – consider pump weight and ease of deployment if frequent relocation is needed.

5. Maintenance and Serviceability

While submersible slurry pumps generally require less alignment and installation effort than horizontal units, serviceability still matters.

- Look for modular designs that simplify impeller or seal replacement.

- Verify spare part availability from the supplier.

- Consider the long-term total cost of ownership (TCO), not just purchase price.

Maintenance and Performance Best Practices

Even the most durable submersible slurry pump requires consistent upkeep to ensure reliability and efficiency. A structured maintenance plan not only extends pump life but also minimizes costly downtime in critical operations.

Routine Inspection Schedules

- Daily/Weekly Checks: Monitor for unusual vibration, noise, or heat.

- Monthly Checks: Inspect seals, bearings, and power cables for wear.

- Quarterly/Annual Checks: Evaluate impeller wear, motor insulation resistance, and overall performance efficiency.

Seal and Impeller Care

- Mechanical seals are the most vulnerable components due to their constant exposure to slurry.

- Inspect regularly for leaks or abrasions.

- Replace seals promptly to avoid motor damage.

- Inspect regularly for leaks or abrasions.

- Impellers should be regularly monitored for signs of wear or imbalance.

- Open impellers are easier to clean but may wear out faster.

- Closed impellers last longer in abrasive applications but require careful monitoring for efficiency loss.

- Open impellers are easier to clean but may wear out faster.

Preventive vs. Reactive Maintenance

- Preventive approach reduces unexpected breakdowns, extends equipment life, and ensures predictable operating costs.

- Reactive maintenance, though sometimes unavoidable, leads to unplanned downtime and higher emergency repair expenses.

Safety Considerations During Operation

- Ensure that all electrical connections are properly insulated and comply with site standards.

- Verify that the pump remains fully submerged to prevent overheating.

- Always follow lockout/tagout procedures during servicing.

- In hazardous locations, electric submersible slurry pumps should be equipped with explosion-proof motor enclosures.

Why Submersible Slurry Pumps Matter for Your Projects

The submersible slurry pump stands out as a versatile, durable, and high-performing solution for industries that deal with abrasive slurries and solids-laden fluids. From mining and dredging to wastewater management and construction, these pumps combine reliability with efficiency, helping teams maximize uptime and reduce operating costs. If you are looking for guidance on selecting or deploying the right slurry pumping system, we at NY Dredge are here to help. Discover our expertise and solutions, and let us support your next project with equipment designed to deliver results where it matters most.